Look at the material weight

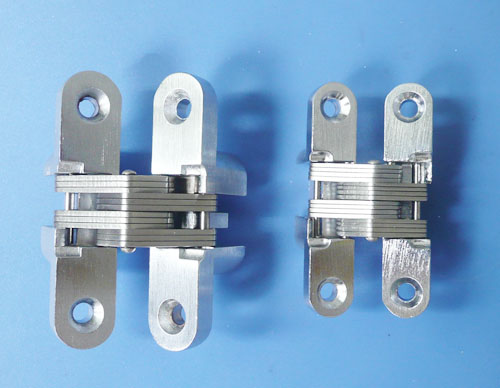

Hinge quality is poor, cabinet door used for a long time is easy to back up, loose and sagging. Cabinet hardware almost all use cold rolled steel, one-time stamping molding, feel thick, smooth surface. Moreover, because the surface coating is thick, it is not easy to rust, strong and durable, and strong bearing capacity, and the poor quality hinge is generally made of thin iron sheet welding, almost no resilience. If it is used for a long time, it will lose its elasticity, resulting in the cabinet door not tightly closed or even cracked.

Experience the touch

Hinges with different advantages and disadvantages have different hand feeling when using. The hinge with excellent quality has soft force when opening the cabinet door. When it is closed to 15 degrees, it will automatically rebound, and the resilience is very uniform. Consumers can open and close the cabinet door to experience the hand feeling.

Look at the details

The details can show whether the product is excellent, so as to confirm whether the quality is outstanding. The hardware used in high-quality wardrobe hardware is thick and smooth, and even achieves the effect of mute in design. Low quality hardware is generally made of cheap metal such as thin iron sheet, and the cabinet door is stretched raw and even has harsh sound.

Besides visual inspection and hand feeling, the surface of hinge should be smooth, and the reset performance of hinge spring should be paid attention to. The quality of the reed also determines the opening angle of the door panel. The good quality reed can make the opening angle exceed 90 degrees.

Tips

The hinge can be opened to 95 degrees, and the two sides of the hinge can be pressed by hand to observe that the supporting spring does not deform or break. The product with strong quality is qualified. The service life of inferior hinge is short and easy to fall off, such as cabinet door and hanging cabinet falling down, which is caused by poor quality hinge.